Algae – design and implementation of cultivation and downstream technology

We offer our Clients comprehensive outsourcing services in the field of research and development (R&D) regarding micro- and macroalgae – cultivation in closed systems and biorefining.

Our team of experts has many years of experience in research and implementation projects, providing innovative solutions tailored to the needs of our Clients.

Scope of our services

- Culture and optimization of microalgae growth conditions

- Selection of suitable microalgae strains depending on the application.

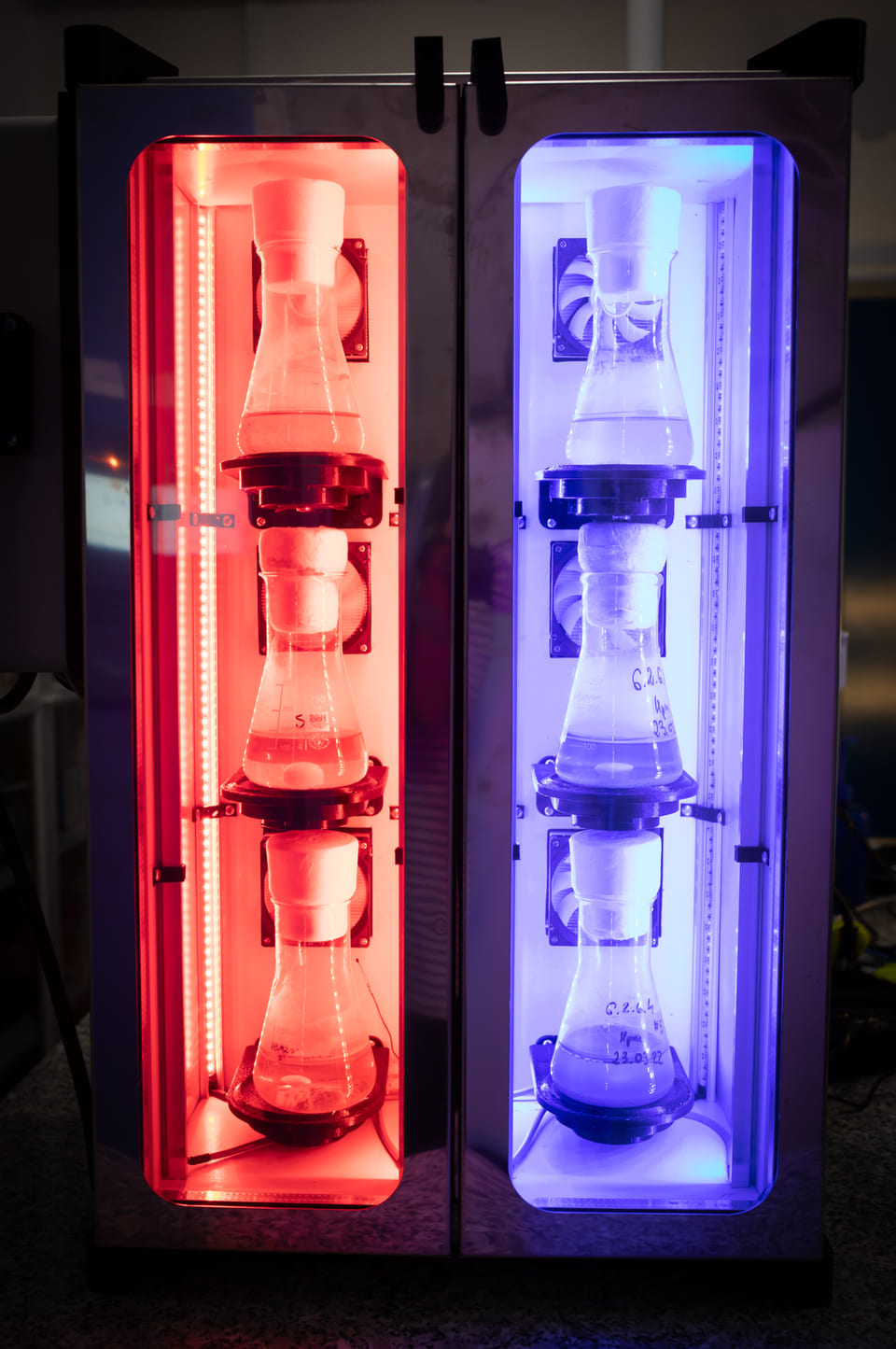

- Design and implementation of culture systems (open and closed systems, i.e. air-lift photobioreactors, pools etc.).

- Optimisation of environmental parameters (temperature, light, medium composition).

2. Biochemical analyses and characterisation of microalgae

-

Identification and analysis of biochemical composition (proteins, lipids, carotenoids, polysaccharides).

-

Assessment of bioenergetic potential (biofuel production).

-

Study of antioxidant and health-promoting properties and assessment of potential applications in various industries.

3. Development and implementation of biomass processing technologies

- Development of methods for extraction and purification of desired compounds depending on the application (incl. feed, food, cosmetics, pharmaceutical and bioenergy industries).

- Minimisation of production costs and process optimisation, i.e. identification and valorisation of co-products (sequential biorefining).

4. Industrial applications and pilot projects – scaling up

-

Organisation and supervision of testing under laboratory and pilot conditions (production scale).

-

Design, construction and integration of complete full-scale production installations.

-

Process improvement through optimisation and introduction of automation solutions.

Technology consultancy

- Selection of suitable strains, raw materials and technologies, as well as the possibility of using those existing ones.

- Determination of possibilities of adapting existing solutions.

- Applications of main products and methods of managing process by-products.

- Execution of research into novel biorefining methods based on the principles of Green Chemistry and the Circular Economy Model.

- Collaborate with scientific and research entities in the implementation of innovative process and product technologies.

- Implementation of solutions based on current industry knowledge and the latest scientific developments.

Benefits for our Clients

- maximisation of raw material use

- multiproductivity

- reduction of waste generation and valorisation of process by-products

- support of sustainability and circular economy objectives

Each project is individually tailored to the client’s unique requirements and expectations. We use modern tools and methods to guarantee the highest standard of service. We offer support at every stage of implementation – from project conception, through the entire R&D process (laboratory stage and scale-up), to production line design, real-world testing and full implementation.

Stages of our service:

Identification of Client needs

– in-depth analysis of requirements and expectations

Assessment of potential

– analysis of the possibility of using raw materials, main products and co-products obtained, together with an assessment of the possibility of their valorisation

Concept development

– development of a detailed technological design together with an implementation schedule

Project implementation

– execution of pilot tests, execution of the scaling process, integration of systems and launch of operations

Post-implementation support

– ongoing monitoring and optimisation of implemented solutions

Cosmetic and medical products

Laboratory tests on cosmetic and medical products

Our offer also includes comprehensive laboratory analyses of cosmetic products and medical products.

For years, we have been conducting advanced research into extracts of natural origin, particularly algal compounds. Access to the highest quality raw materials and a well-developed technological background ensure the highest quality of services and allow us to carry out processes on both laboratory and industrial scales. The products we supply meet the highest standards of quality as well as innovation. Our team of experienced experts ensures that services are carried out in accordance with current standards and regulations, providing reliable results and the highest quality analyses in accordance with ISO and GMP standards. We provide full technical support in scaling up the process from laboratory to industrial scale.

Scope of our services

1. Formulation development

Formulation design of cosmetics and medical devices in accordance with current standards, together with close monitoring of each stage of production. Advice on product formulation – selection of active substances, preservatives and optimisation of production. Careful selection of raw materials, stability tests and assistance in the selection of suppliers.

2. Formulation optimisation / reformulation

Modification and refinement of formulations to ensure that a product with the intended properties is obtained. Refinement of existing products to increase process efficiency, improve safety and performance of a product. Detailed product formulation analyses. Adaptation of formulations to market requirements.

3. Aging tests – stability and shelf-life studies

Laboratory testing of finished products, including analysis of physico-chemical changes in the product identifying their cause and indicating possible ways of eliminating them. Centrifuge and temperature tests. Advanced ageing tests conducted under special conditions to confirm product quality and stability. Selection of packaging and verification of its compatibility with the product. Control of packaging tightness and stability. Description of product storage and use conditions.

4. Physico-chemical analyses

Comprehensive testing of product composition and purity and testing of compliance with current standards. Determination of viscosity and density, measurement of pH and melting point, organoleptic analyses. Advanced rheological analyses (viscosity tests) and viscometric analyses. Determination of foaming properties. Detection of heavy metals.

5. Microbiological analyses

Analyses to identify potential product contamination. Determination of the number of micro-organisms (bacteria, yeasts, moulds), detection and determination of Escherichia coli, Staphylococcus aureus, Pseudomonas aeruginosa, Candida albicans, Enterobacteriaceae.

6. Tests of preservative properties

Evaluation of the effectiveness of preservatives as well as active substances. Tests to guarantee product shelf life, carried out in accordance with the Pharmacopoeial method, the Koko test and the PE-EN ISO 11930:2012 standard.

7. Application analyses

Formulation testing to determine the lubricity of the cosmetic. Testing of product viscosity and density.

Benefits for our Client

- maximising the efficiency of the production process, thereby reducing waste and optimising costs

- support for product innovation

- guaranteeing product quality, safety and efficacy

- ensuring product compliance with ISO and GMP standards

- adaptation of the product to market requirements

- full support in scaling up projects

Our offer combines advanced scientific knowledge, advanced technologies and a customised approach to each project. We offer full support in the creating and analysis of cosmetic and pharmaceutical products, with an emphasis on innovation, safety and compliance with current standards. We are committed to building lasting relationships with our clients, which is why we carry out each order with the greatest attention to detail, tailoring solutions to individual needs. We are convinced that thanks to our services, our clients are able to launch cosmetic and pharmaceutical products that meet the highest quality standards.

Cannabis

Cannabis cultivation under controlled conditions

We provide comprehensive support for Cannabis cultivation, including both the selection of suitable varieties and the design and optimisation of technological processes. Our offer is aimed at producers of dietary supplements, cosmetics and pharmaceuticals who are looking for reliable, effective and regulatory-compliant solutions.

Scope of our services

- Selection of customised Cannabis varieties

We assist in the selection of suitable Cannabis varieties, taking into account the cannabinoid profile, intended use and growing conditions to ensure optimal results.

2. Advice on growing conditions

We offer support in designing and optimising the growing environment, including:

- comprehensive design and production of closed plant-growing systems – we select appropriate hydroponics, aeroponics, fogponics, etc., according to the available resources,

- selecting the right fertilisers for hydroponic and aeroponic cultivation – ensuring nutrients are optimal for the development stage of the plants,

- designing LED lighting systems – adapting the light spectrum to the growth phases of the plants,

- water purification and dosing systems and air conditioning – maintaining optimum humidity, temperature and low levels of microorganisms and fungal spores.

3. Support in the care, pruning and cloning of plants

We provide advice and support on cultivation techniques that maximise the yield and quality of the raw material.

4. Design of the extraction line and processes

We offer comprehensive consulting and R&D support for the development, optimisation and scale-up of extraction and purification processes for cannabinoids and other active substances. Through advanced technologies, we enable high purity of active ingredients that meet the highest quality standards.

Technology consultancy

- Comprehensive audit at the client’s site, with regard to the possibility of growing plants and extracting active substances.

- Consultancy as well as research and development of selective extraction methods.

- Development and optimisation of processes for purifying ingredients to API purity.

- Research into the transformation of individual cannabinoids (biotransformation).

Scaling up production – from laboratory and semi-technical to full industrial scale.

Benefits for our Clients

- individual and flexible approach – tailored to specific needs

- cost reduction – through process optimisation

- higher product quality – in line with market and regulatory requirements

- safety and compliance – meeting the highest quality and regulatory standards

Our interdisciplinary team consists of specialists from the fields of biotechnology, agronomy, chemical engineering and extraction technology. With a wealth of experience and expertise, we provide proven and innovative solutions tailored to the individual requirements of our Customers.

Feel free to contact us!

E-mail: